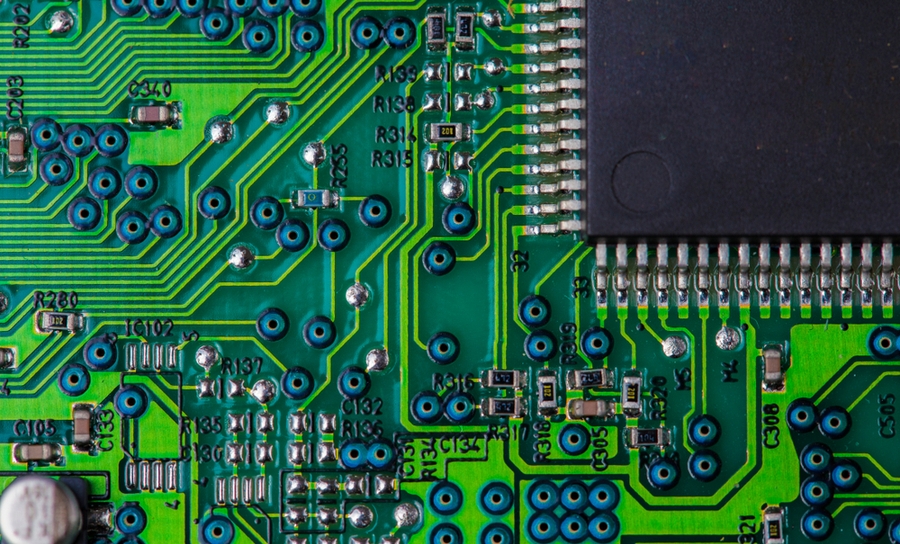

PCB or printed circuit board production has increased over the recent years. Many companies have emerged to offer PCB services to clients and satisfy their needs in various applications. The modern technological advancements have also made PCB production cheap fast, and efficient, among other benefits. Manufacturing is done based on the customer’s wants or the purpose of the PCB. The massive creation of PCBs is a result of multiple advantages. In this post, we dive into the PCB benefits.

Reasons why PCBs are used in many applications

As mentioned above, manufacturers are making PCBs in plenty, unlike in the past years. Some reasons for this include;

1. Time and energy saving

Traditional manufacturing methods were slow, time-consuming, and inconvenient, unlike the modern methods of assembly. The PCB assembly process is fast; thus, the product is released into the market within a short period. The production process also consumes less energy, considering the time is cut down by more than half that used in traditional assembly.

2. Affordability

Developing a PCB prototype helps to reduce the overall cost of the procedure plus the goods. After creating a design prototype, the designer ensures no errors are present, and the PCB is fit for production. Once manufactured, testing is conducted to ensure its viability. Dealing with a single item prevents extra costs incurred if the PCBs were produced in bulk and present some errors. Also, PCBs are generally cheap as the materials used are readily available and affordable.

3. Lightweight nature

PCBs are naturally light compared to other circuit boards. In addition, advanced technology is used, which allows it to power electronic devices no matter the size. This is made possible by the copper wires present within it, which are highly conductive and perfect for current transmission

4. Reliable and easy to repair

When a manufacturer produces a PCB, they perform product testing to detect errors before being presented to the market. This act makes it efficient and effective for use in the intended application. In case of any mistake, it is easy to fix the PCB and develop something new. Outside the manufacturing plant, PCBs are easy to repair if electrical issues develop in the electronic device. During the layout design process, PCBs are marked to locate each component. The marked features make it easier to find the element that’s causing the problem.

5. Fixed position

PCBs are a particular spot they occupy in every device. It’s therefore easy to locate them for its maintenance and that of the components on it. Its fixed position helps the electronic elements stay in place even when the board gadget is moved.

6. Minimal electronic noise

PCBs are known to emit noise in the form of radiation or heat. Typically a well-assembled PCB produces no noise, thereby having its performance levels at a high level.

Conclusion

PCBs are beneficial in many ways, to name a few. Their production process is automated, which is a plus for both the manufacturer and client. It saves on time and cost; hence many are produced within a short time. Technological advancements ensure the use of PCBs continues and provide a good working environment for electronic devices.