The CNC milling machine focuses on milling. That is, it involves procedures where rotating tools are utilized in removing material from a workpiece gradually. In most CNC machine shops, you will find the CNC milling machine. Additionally, the machine makes the CNC milling parts highly precise, thus guaranteeing quality. The device also has several features. Each part plays a crucial role in the manufacturing process. Therefore, this article aims to inform you of the CNC milling machine parts.

The CNC milling machine parts

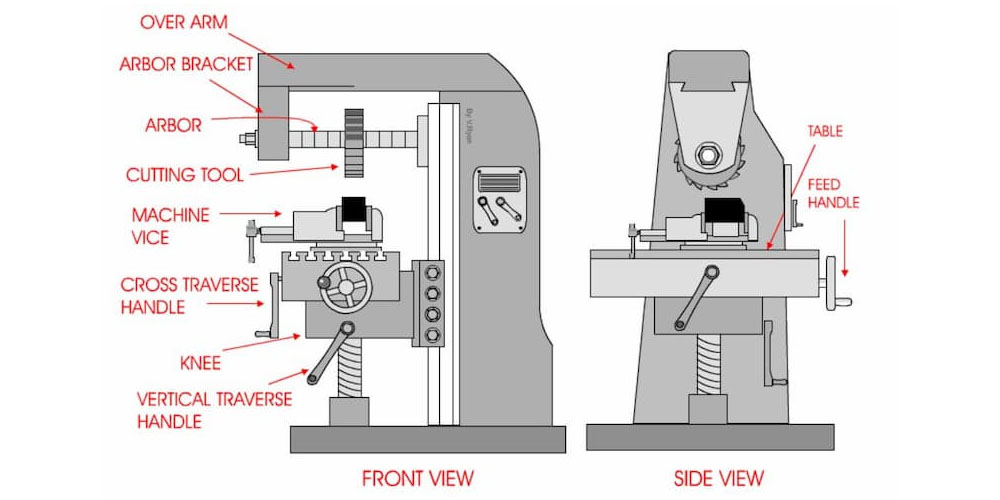

1. Table

The table offers a solid base for holding the workpiece. It can also be used for mounting vices or fixtures, ensuring the piece is held in place. The majority of the CNC milling machine table utilizes the T-slots for attaching workpieces to the table.

2. Frame

The frame offers support to the machine and ensures its sturdy enough to resist the cutting pressures. The frame usually consists of a base whose column is detachable. Additionally, its frame is made of iron. The frame’s headstock is the crucial part of the frame. It is where the machine’s primary spindle is mounted. The headstock stability ensures that the device does not chatter or vibrate during the production process. An unstable headstock could lead to machining errors. It could also ensure that the milling machine has a short lifespan.

3. Axes

The axes use the cartesian coordinates to allow for motion. The coordinates are programmed through manual jogging and g-code from the control panel. Three main axes correlate with the X, Y, And Z. Some milling machines have a fourth axis that acts as an accessory. Some even have up to 5 axes, but they are not common.

4. Spindle

The spindle is the CNC milling machine’s heart, and it consists of a tapered region and rotating assembly. The tapered region acts as a place that tool holders can be placed. Additionally, tools are usually attached to the spindle’s shaft. During the machining process, the spindle is rotated with the help of the motor. Furthermore, it is essential to maintain the spindle to ensure optimum operation. One of the best ways to maintain it is through lubrication.

5. CNC controller

The CNC controller is the CNC milling machine’s brain. The controller consists of electronics that push the motors to ensure axes movement. Additionally, CNC controllers are in charge of accepting manual inputs and G-code from the control panel and changing it into suitable signals that control the motors or Axis Stepper.

6. Cutting tool

The cutting tool’s function is as the name suggests. Its function is cutting as commanded by the operator. Additionally, it is attached to the column.

7. Column

The CNC milling machine can have either a single or double column. The type of column used depends on how intricate the part being manufactured is.

8. Coolant tubes

The coolant tube’s primary function is to ensure that the metal and cutting tool is cool. It also ensures that the cutting tool is well lubricated.

Conclusion

The CNC milling machine is essential. It contains several parts, as you can see from above. Each part plays a crucial role in ensuring the device operates wells. Furthermore, proper maintenance of each machine part guarantees its durability.