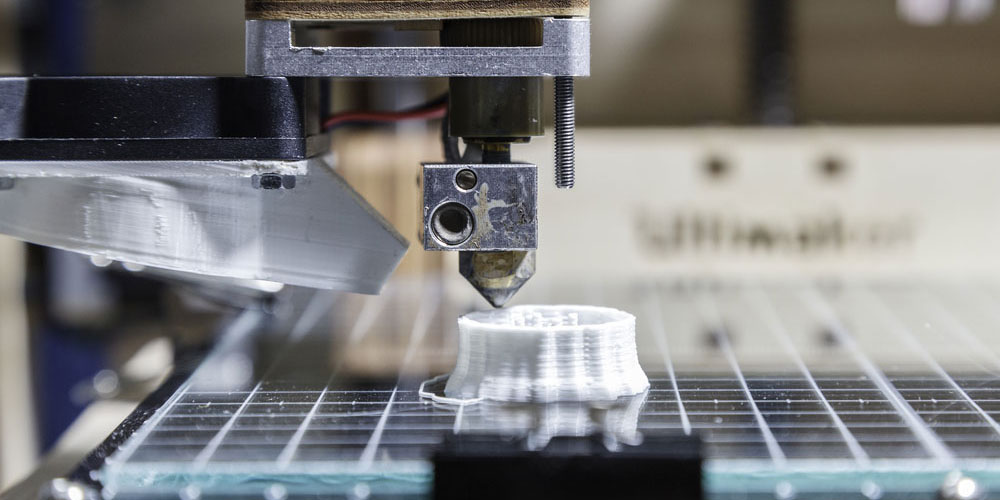

Rapid prototyping can be described as a quick process of creating product models using a 3D CAD. Several rapid prototyping companies have adopted this method to replace handcrafted methods of production.

One major reason rapid prototyping is becoming more popular is that they reduce the time spent on realizing product prototypes. Also, it enables product designers to create and present fresh ideas and concepts to their customers. These clients can, in turn, approve the product development if they are satisfied with the prototype.

The concept of rapid prototyping is quite broad; want to find out more? In this piece, you will learn about the benefits, limitations, and applications of rapid prototyping. Keep scrolling!

What are the benefits of rapid prototyping

There are a lot of things you can achieve with rapid prototyping. Some of them include but are not limited to:

- Reduces cost and time spent on development.

- Allows the product designer to make corrections, modify, or generally improve the final result.

- Rapid prototyping allows you to adequately communicate your design concept.

- Rapid prototyping allows the product designer, final consumer, client, and other users to experience the product and give feedback immediately.

- The product’s functionality and concept can be tested to finalize its specification

Applications of rapid prototyping

Rapid prototyping can be applied in different industries. You can find it applicable in the following sectors:

- Mechanical sector

- Automotive sector

- Medical sector

Ultimately, rapid prototyping can be used in different stages of every production cycle. From the design phase to functionality tests, and presentations.

Types rapid prototyping

Selecting the exact rapid prototyping technique is the first step to succeeding with a prototype. Each technique comes with its speed, cost, development, and fidelity level.

You don’t have to limit rapid prototyping to a single process as different manufacturing methods to arrange a prototype.

That being said, below are some types of prototyping techniques that product designers can adopt.

- Selective laser sintering (SLS)

- Additive manufacturing

- Directive metal laser sintering (DMLS)

- Binder jetting

- Fused deposition modeling (FDM)

- Poly jetting

- Binder jetting

Other techniques to consider during rapid prototyping include:

- Investment casting

- CNC machining prototyping

- Vacuum casting

Limitations of rapid prototyping

- It can get expensive. If you’re operating on a budget, then rapid prototyping might be the wrong idea

- Requires experienced labor

- There are little to no adequate materials to use for production

Guidelines for creating an awesome prototype

To make a great prototype, you can follow the guide below:

- Verify the 3D file. Ensure that the mesh f your 3D model is correctly closed

- Check to see that the minimum thickness of the prototype is larger than 1mm.

- Verify the tolerance. The tolerances of the technology and material selected for the prototype are compatible enough to handle your project.

Final thoughts!

In all, rapid prototyping has gone on to become one of the biggest innovations in recent times. That’s because different development and research departments can use it to design, analyze, test, and optimize products in rapid successions.