The portable crushers have greatly influenced industrial and environmental applications. From quarrying and mining to recycling, these versatile machines adapt to a range of operations. Stationary systems aren’t always viable, and their mobility and efficiency provide cost savings and environmental benefits. From fixed to portable systems, this is a leap in innovation as it addresses contemporary needs in flexibility and sustainability.

Role of portable crushers in quarries

The raw materials, such as stone and gravel, are extracted and processed in quarrying. The process is complex due to the scale of operations and the vast amounts of weight that need to be moved. Portable jaw crushers work well in such environments. Primary crushers are designed to handle the sizeable raw material feed sizes while reducing the received material to sizes suitable for transmission to the following process stage, typically primary, secondary, or tertiary crushers. With rugged construction, they can withstand harsh conditions.

One advantage of these crushers is their portability. They can be distributed across the site with movement, minimizing the need to fold materials over long distances. This leads to reduced fuel consumption and operational costs. Mobile crushers can handle granite or other rigid materials, offering the reliability necessary for demanding quarrying tasks.

Portable Crushers and Recycling Applications

Recycling is essential in waste management and construction. Concrete, asphalt, and other debris are generated during demolition projects that would otherwise find their way to landfills. Portable impact crushers can recycle these materials. Horizontal shaft impactors are used primarily for crushing, while the vertical shaft impactor is used for fine crushing and particle shaping.

Recycling using these crushers offers several advantages. They also produce aggregates with uniform properties that can be reused in construction. Deployed and used by the public, these machines facilitate environmental goals and foster environmentally responsible practices. They simplify operations because the crushing process is brought to the site, saving time and resources.

Mobile Crushers Key Features

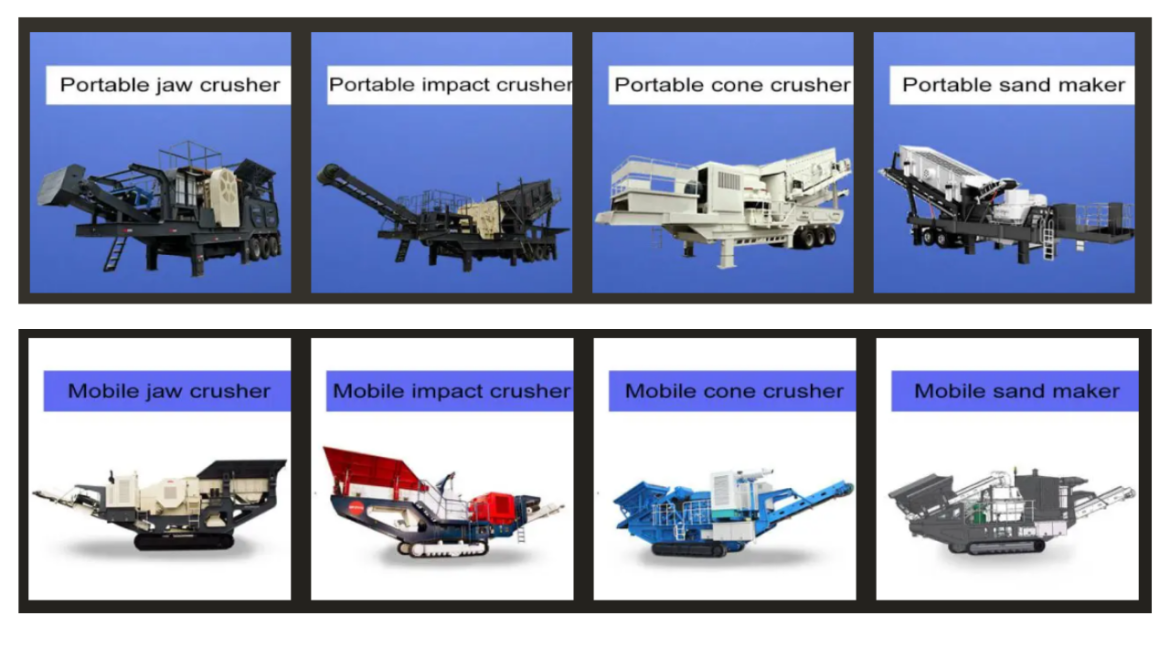

Portable crushers are unique because of their mobile nature and flexible demands. Wheel-mounted and track-mounted options allow for quick movement and deployment. They can handle different input sizes and vary output capabilities, making them suitable for numerous applications.

Energy efficiency is another highlight. These crushers employ many electric drives that are energetically cheaper. It reduces operating costs and promotes environmentally friendly practices. These advanced safety features, such as remote operation and automatic blockage clearing, improve usability and make working conditions safe.

Better Performance through Technological Advancements

Modern mobile crushers use the latest technologies to enhance efficiency. They also enable real-time diagnostics to monitor operations and catch problems early. Hydraulic systems ease maintenance and facilitate quick changes. Their innovation decreases downtime and increases productivity.

They are also integral in terms of noise and dust reduction. These crushers that do not increase impact on surrounding areas comply with environmental standards. They are suitable for use in an urban setting since they are noise- and air-quality-free.

Advantages Compared With Traditional Stationary Systems

These crushers are unrivaled in their flexibility. Stationary plant setup is cost and time-intensive. On the other hand, they can be operational in hours. Being mobile, you can shift them between sites, which is ideal for temporary projects.

Another advantage is cost efficiency. Processing materials on-site lowers the cost of hauling. Additionally, they consume less fuel, which further helps to reduce expenses. Therefore, these machines can handle multiple tasks and are excellent value for money. They can quickly meet various needs, whether you need to manage a quarry or recyclables project.

Future Prospects of the Portable Crushers

They have great potential for the future as they continue to develop and improve. The integration of artificial intelligence and the Internet of Things will enable predictive maintenance and greater automation. With these features, operations will be streamlined, and reliability will be improved.

It will also use sustainability. Mobile crushers could become even greener through innovations like renewable energy integrations. With industries putting more and more emphasis on efficiency and environmental friendliness, these crushers are likely to evolve into applications beyond quarrying and recycling.

Conclusion

Portable crushers are almost essential to bridge the gap between quarry and recycling operations. Across industries, their mobility, efficiency, and versatility make them a valuable asset. They adapt to dynamic demands and provide flexible, cost-effective, sustainable solutions. With technology constantly progressing, such crushers will always be on the cutting edge of innovation and able to handle the challenges of the years to come.